Please consider this scenario: One-hundred twenty days ago a Magnitude 7-plus earthquake hit a dense urban area. More than 2.3 million people are crowded into a roughly 25 mile by 6 mile matrix between a treacherously rocky littoral and high mountains. Almost everyday since there have been multiple after-shocks, many between M6 and M7. At least 28,000 have been killed, more than 67,000 have been injured. Three-quarters of the population is displaced into tents and other temporary shelters. At least sixty percent of residential housing is now uninhabitable.

The grid is gone. Solar and fossil-fuel emergency generators continue to deliver sparse flows of electricity. The water network has been decimated. Telecommunications is unreliable and from time to time has been mute for several consecutive days. Every hospital has been seriously damaged. Four of five leading grocery distribution centers have been destroyed. Fifteen commercial-scale bakeries have survived or been reopened, but output is sporadic.

Freight routes through the surrounding — still seismically active — approaches are narrow and susceptible to unpredictable landslides. Maritime infrastructure has been destroyed, previous navigational channels are unusable. For four months now inbound flows of water, food, fuel, pharmaceuticals, medical goods, and other essential freight have been about two-thirds below ordinary pre-event volumes. Redistribution of this seriously reduced flow is slowed — often stopped — by recurring aftershocks, disrupted transportation networks, poor communications, lack of local trucking, and other usual suspects.

Significant supplies are now staged outside the impact zone, some as close as thirty miles away. But — so far — there has been no way to sustainably increase inbound capacity. The best available estimates indicate that at least 900,000 residents are “facing extreme food shortages, acute malnutrition and disease levels are excessively high.” Another 400,000 are on the edge of imminent starvation.

This is a dense urban area in an isolated geography that has been — is being — seriously disrupted by seismic activity. Mass evacuation is essentially impossible given currently available transportation/shelter capacity constraints and seismic-related impediments.

Many geologists perceive the seismic activity will continue. There is credible concern regarding the prospect of even more destructive seismic events. Your current strategic context is treacherous. Your strategic options are austere. The context could soon become even worse and your options could be further constrained.

Given this scenario: What is your Supply Chain Resilience strategy? How can you practically engage this intractable problem with creativity and commitment? What is the best you can do? Where and how do you focus? What are your triage principles? To reasonably advance your strategy, what are your minimum operational requirements? Given this scenario’s lack of detail, it is probably premature to outline your tactical priorities and sequence, but please flesh out your minimum operational requirements with concrete examples.

Of course, this scenario — except for cause and topography — mirrors what is happening in Gaza now (more and more and more and more and more and more). Does that change your strategy? Your operational requirements? If so, why? If so, how? Given your “why” answer, what should you — and I — do next?

+++

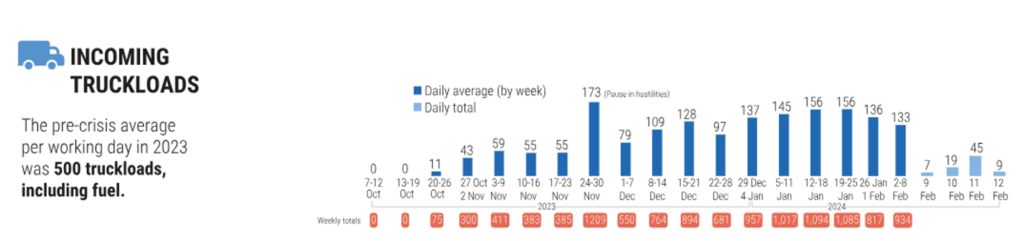

February 13 Update: Flows go from bad to worse. Below is the OCHA update on truckloads. This contrasts with the COGAT update reporting 174 truckloads for February 12. This data discrepancy is sometimes resolved over a few days (but not always). This data gap is also wider than any I have seen previously. (More and more and more.)

February 14 Update: Today’s Financial Times gives considerable prominence to a so-called “explainer” headlined: Why Desperately Needed Aid is Failing to Reach the People of Gaza. If you have been reading this blog (here and here and here) nothing will be new to you, but it is a concise summary from a credible source. (More and more and more and more.)

February 15 Update: I have received several inquiries related to UNRWA activities in Gaza (and the West Bank and Jordan). Here is some recent background from the Washington Post. I previously addressed this issue in a January 31 Update. But my admittedly technocratic “response” is probably best articulated in the following statement of a core Supply Chain Resilience principle included in a December 9 post (well before the most serious critiques of UNRWA emerged).

Supply Chain Resilience acknowledges that contemporary high volume, high velocity flows of essential human resources serving large populations cannot be replaced, even by the most robust and best-organized relief operations. The only effective and timely way to serve large numbers of survivors is rapid restoration and adaptation of preexisting flows. The current situation in Gaza may be the exception that proves the rule. For sixteen years a huge, dense population has depended on robust, well-organized “relief” operations. Sixteen years of relief operations should have signaled an unsustainable situation requiring fundamental reform. But in the very present crisis, this humanitarian supply chain is the only “preexisting capacity” that has the irreplaceable ability to serve survivors.

For many years UNRWA has been the key source of last mile capacity for a significant proportion of the Gaza population. The middle of a flooding stream is not a propitious moment for changing horses, no matter how troublesome the current mount.

February 17 Update: Is available here.